Water treatment

The quality of coating depends greatly on the quality of the water used during the pretreatment process. Tap water quality does not always meet the parameters required by the technological process. For this reason, frequently, it is recommended to use deionizing or reverse osmosis plant, iron removal plants or water softening plants, since high-quality water used in active phases and rinsing improves the coating’s quality and durability.

During some processes, such as the pretreatment of aluminum profiles, the use of deionized water is obligatory.

TAISS SRL offers different types of water treatment plants:

- - deionizing plants

- - reverse osmosis systems

- - water softening systems

These can be supplied as part of pre-treatment plants or as standalone units.

To keep the tanks clean and thus increase the duration of the chemical solutions, TAISS SRL offers:

Oil separators (to keep clean degreasing tanks solutions)

Sludge separator (a system with continuous filtration to separate solid waste).

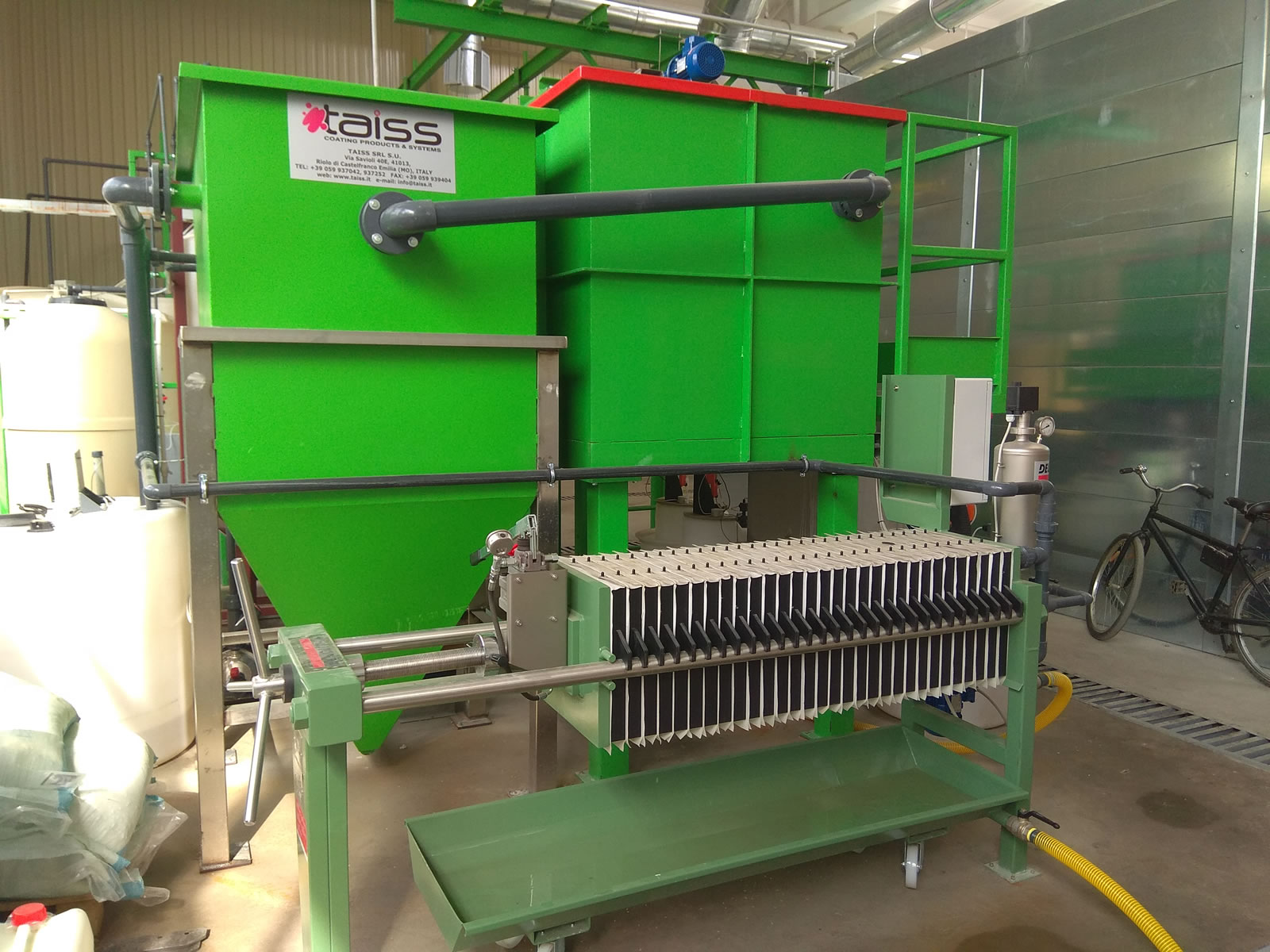

Waste water treatment:

Waste water, incoming from the chemical pretreatment process, need to be treated. We provide automatic plants with different levels of productivity. The standard models are from 1, 2, 4 m³ / hour up to 12 m³. For the final phase of sludge filtration, the plants can be completed with filter bags or filter presses with a further final filtration by carbon filter.

All the water treatment plants are designed to various productivity depending on the Customer needs and they can be installed in a production shops area or in any different location.