Spray booths

“TAISS”® painting booths guarantee a uniform coating, an excellent air suction and an efficient powder recovery. The use of high-quality air filters allows an optimal reduction of dust and the return of exhausted air directly to plant, in full compliance with regulations.

Materials of the booths: plastic or stainless steel.

Recovery systems: cyclones or cartridge filters.

Booths can be fixed or mobile.

In addition to the "classic" booths, TAISS SRL also produces booths for quick color change, with an automatic powder center and a mono-cyclone.

The choice of which booth to install depends on several criteria, including: the number of colors used and the frequency of color changes..

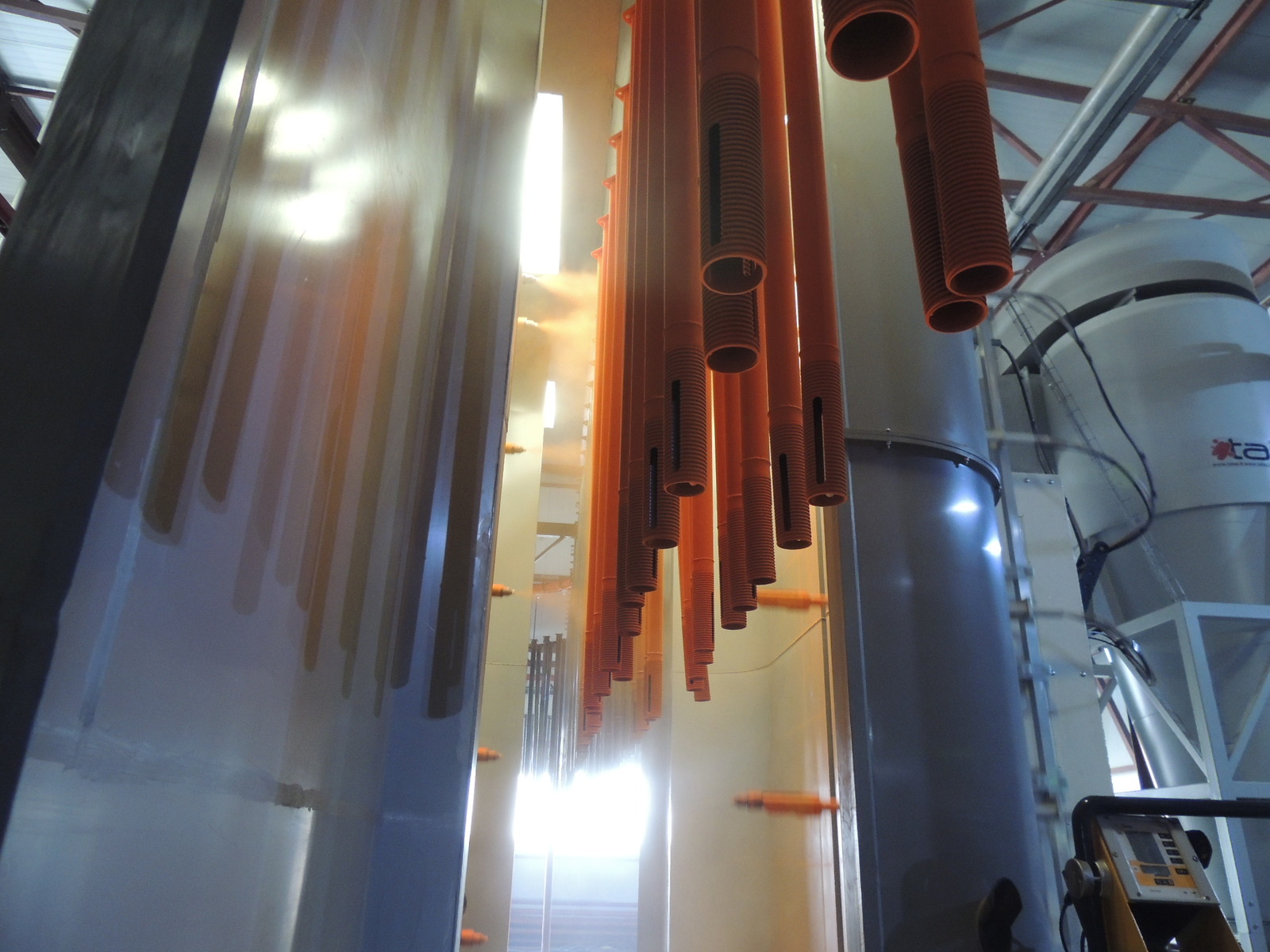

PLASTIC POWDER SPRAY BOOTH WITH MONO-CYCLONE

FOR QUICK COLOR CHANGE

- SUPERIOR SERIES -–

The optimal solution for frequent color changes and high productivity

- Housing made of plastic sandwich panels with rounded edges

- Automatic floor cleaning

- External cleaning of automatic spray guns

- Cyclone with integrated sieve

- Final cartridge filter with backpressure air cleaning

- Final filter with sound insulation

- The piping between the booth, cyclone, and final filter made of stainless steel and externally painted.

- Closing doors for access openings to accelerate color change procedures

- Recovery under the cyclone using a peristaltic pump

- Lighting - LED lamps

- Automatic powder center with the option to draw powder paint from a powder tank or from factory packaging (box)

Demo video

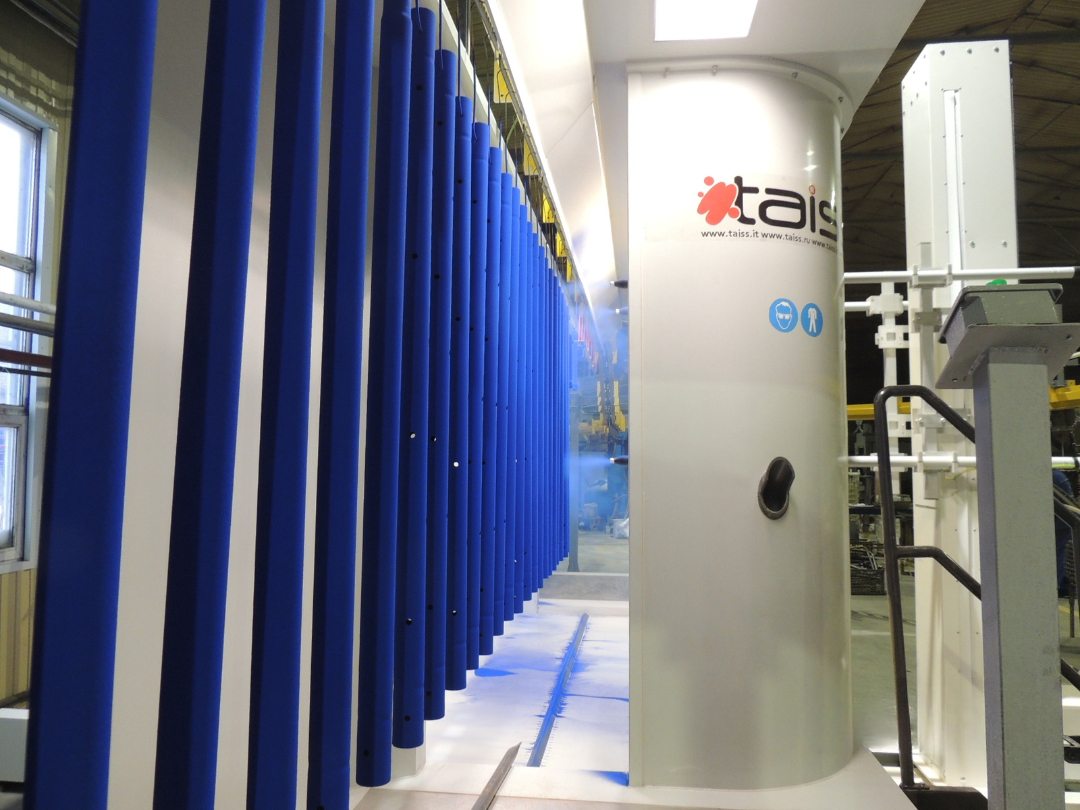

STEEL POWDER SPRAY BOOTH WITH CYCLONES

- BASIC SERIES -

The optimal solution for infrequent color changes

.jpg)

- Stainless steel housing

- Cyclones

- Final cartridge filter with backpressure air cleaning

- Pneumatic filter soundproofing option

- Galvanized pipelines connecting the booth, cyclones, and final filter

- Recovery under the cyclones using a powder pump (Venturi system)

- Powder container with a vibrating sieve

- Booth lighting using LED lamps

STEEL POWDER SPRAY BOOTH WITH FILTERS

- MONO SERIES -–

The optimal solution for working with a single color (maximum 3 colors), or multiple colors without recovery

.jpg)

- Stainless steel housing

- Cartridge filter with cleaning under pressure with reverse air flow

- Recovery under the filtration group by means of a powder pump (Venturi system)

- Powder container with a vibrating sieve

- Booth lighting using LED lamps

- Possibility of adding mobile filter units for each color (in this case, 100% recovery). Maximum number – 3 filtration groups.

In addition to powder spray booths, we manufacture booths for applying liquid coatings, which in turn can be manual or automatic, with dry or water filtration.