AUTOMATIC POWDER COATING PLANTS

These plants include::

- Surface preparation unit for products before painting

- Drying oven after chemical treatment / polymerization of powder coating

- Automatic powder spray booth (with a mono-cyclone and powder center for quick color change, or booths with cyclone or filter recovery)

- Spray guns for applying powder paint (automatic and/or manual)

- Automatic overhead conveyor (monorail or double-rail (P&F)) with continuous or intermittent movement.

Powder coating plants can be supplemented with elements for painting with liquid paints by spraying or immersion (example: application of liquid primer in the painting booth or in a cataphoresis tank before applying the final layer with powder paints).

Here are some examples:

Example 1: Automatic powder coating plant for fences (grids)

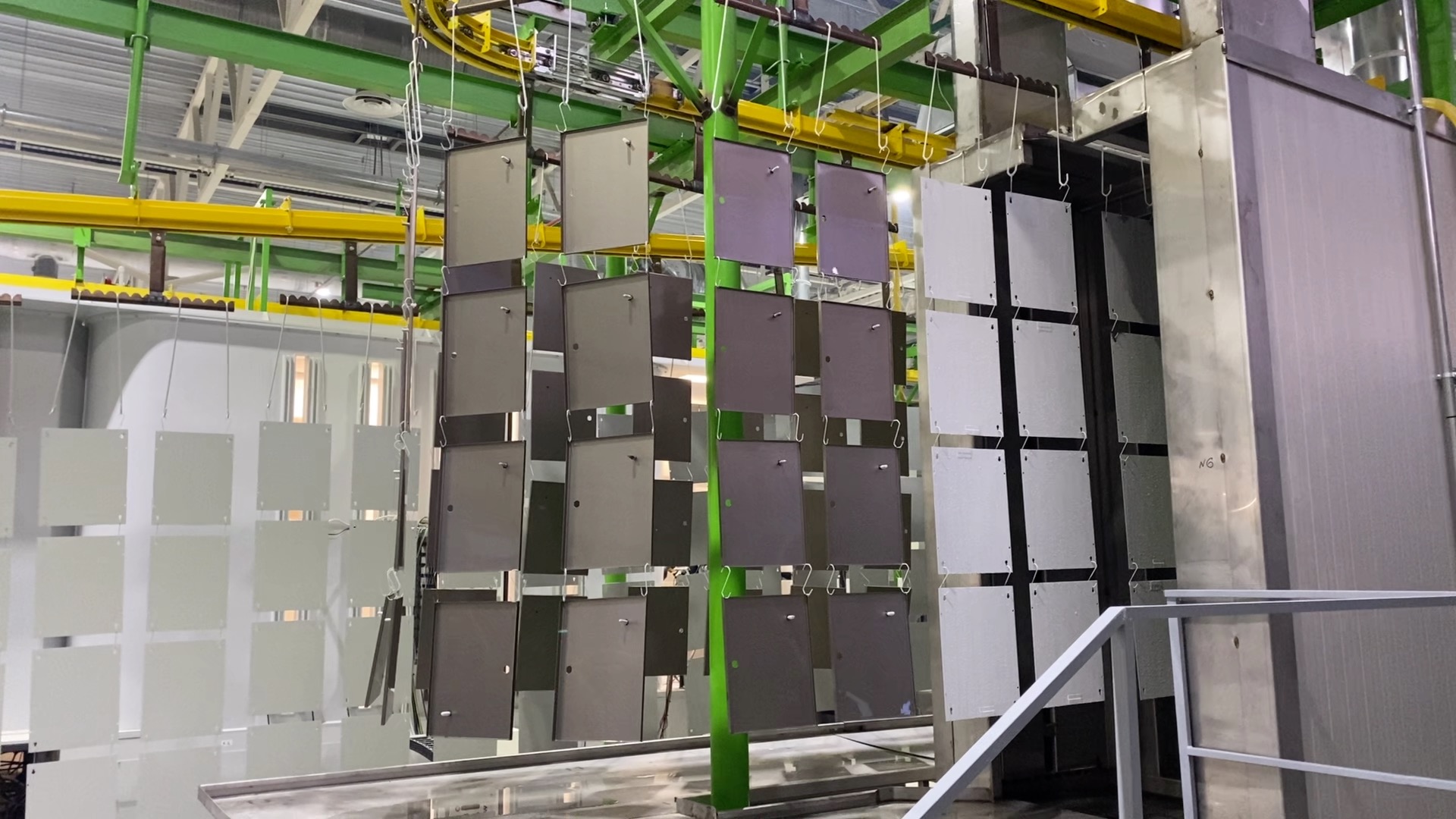

Example 2: Automatic powder coating plant for electrical switchboards

Demo video

Example 3: Automatic powder coating plant for Overhead agricultural machinery

Equipment for agricultural machinery components of different sizes and weights:

Example 4: High-performance automatic powder coating plant for steel profiles