LIQUID PAINTING PLANTS

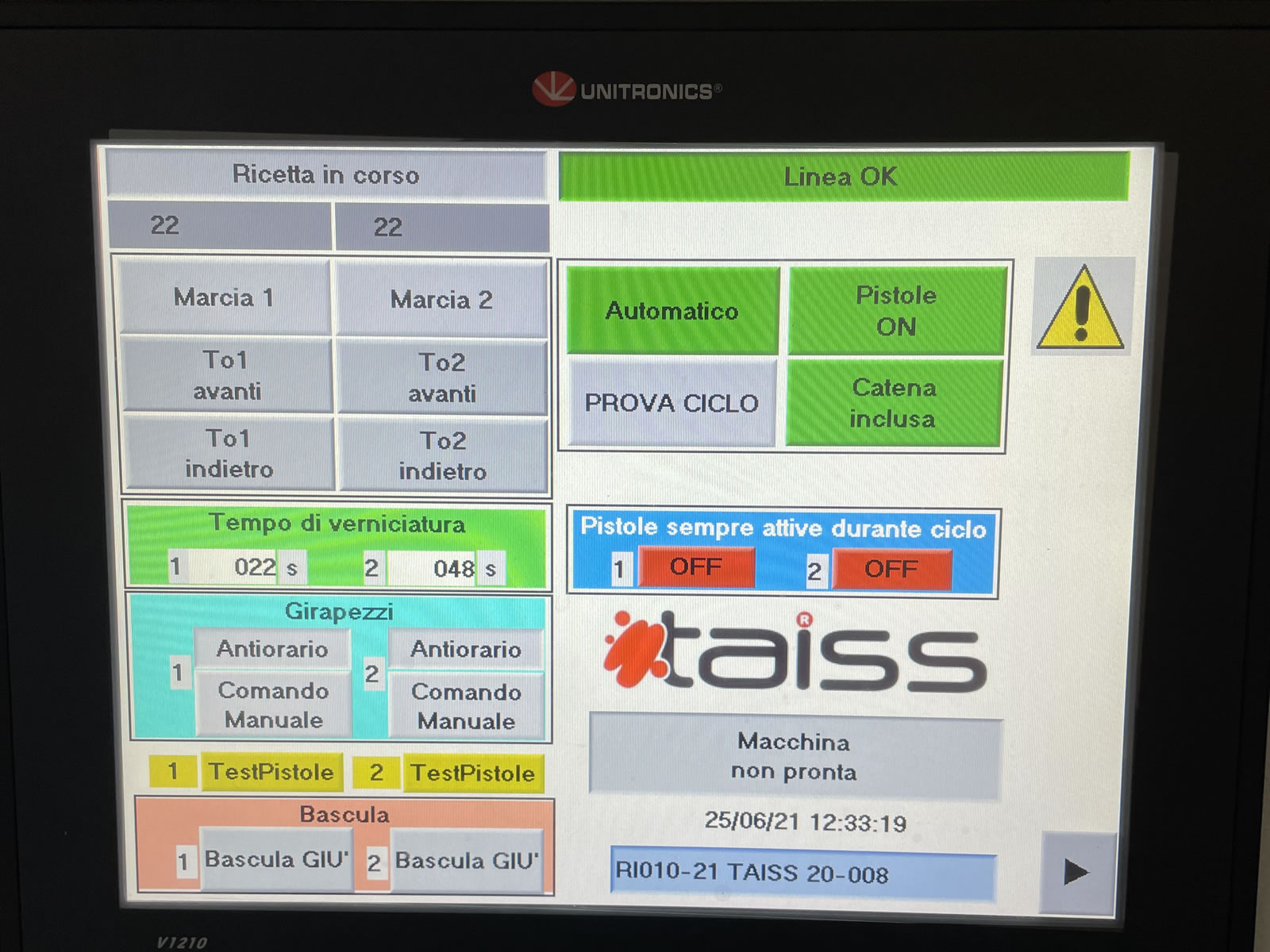

They can be automatic or semiautomatic and include:

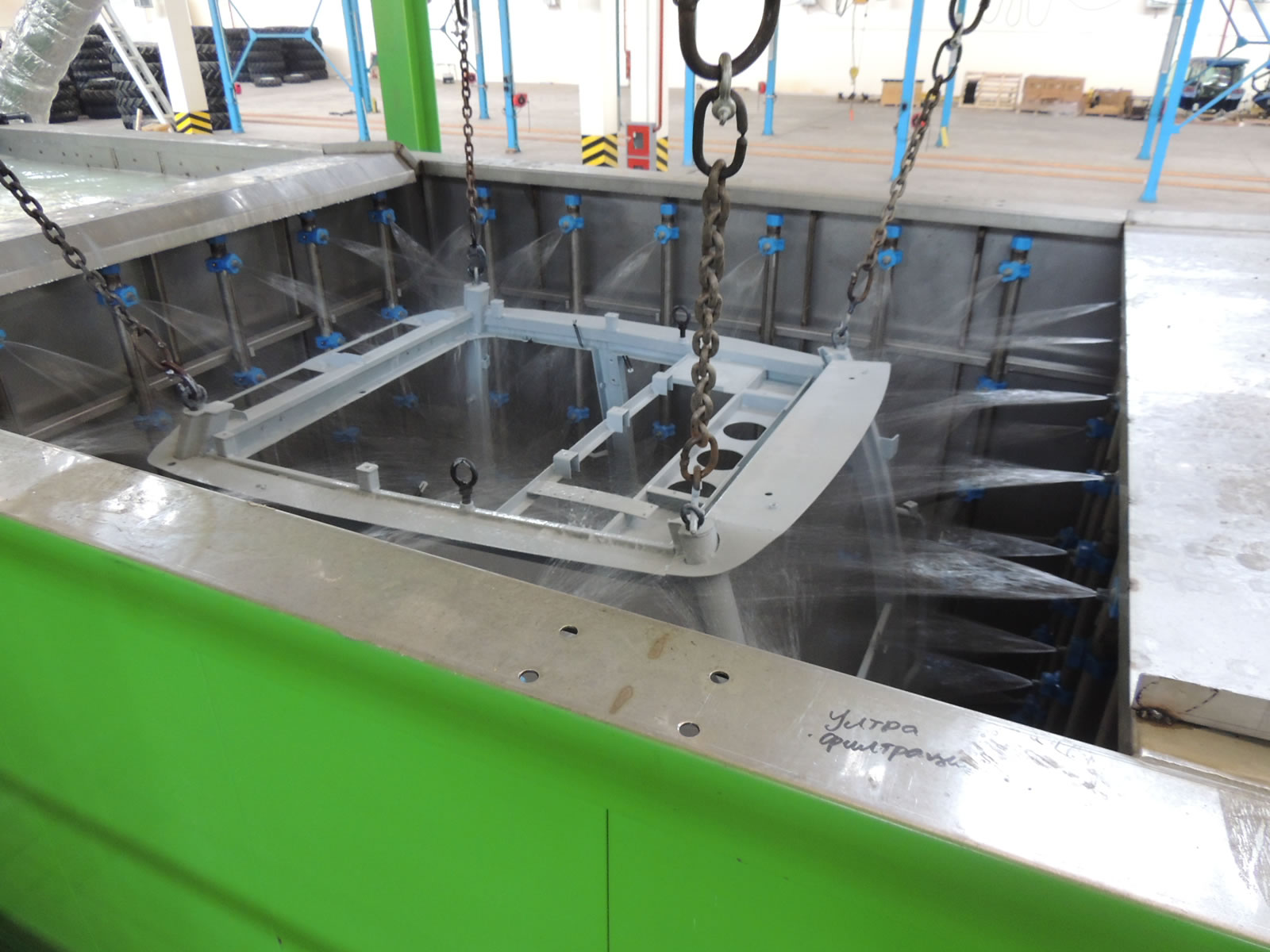

- Chemical pretreatment (spray or dip) and/or shot-blasting

- Liquid painting booths (with dry filtration or filtration by water curtain)

- Pre-drying ventilation booth (including models with heating elements)

- Cooling booths

- Drying ovens for finishing layers;

- Overhead conveyor

Here are some examples

Example 1: Automatic liquid painting plant for agricultural machinery

Painting plants for agricultural machinery components of various sizes and weights.

Max load capacity on traverse - 4,100 kg

Max load capacity on traverse - 4,100 kg

Prodotti: Cabine dei trattori

PRODUCTS: ENGINES

Example 2: Automatic plant for painting pneumatic cylinders with liquid paints

Performance: 50 cylinders/hour